Déconnecté1 888 344-4424EN

-

Champ d’application

- Tous les produits

- Santé - Sécurité

- Prothèses amovibles

- Tous les produits

- Prise d’empreintes et registres

- Coulée des modèles et MEA

- Reproduction de modèle et prothèse

- Cirage & montage

- Mise en moufle

- Acrylique - Bourrage - Injection

- Échaudage - Cuisson - Démouflage

- Meulage / coupage / sablage

- Adaptation

- Polissage - Finition

- Prothèses sur implants

- Réparations - renforts

- Rebasage & Conditionnement

- Autres matériaux

- Accessoires Bucaux

- Boîtes et emballage

- Meubles

- Prothèses fixes

- Tous les produits

- Coulée des empreintes

- Grossissement

- Fabrication des modèles et MEA

- Cirage, maquettes

- Procédé Céramique

- Tous les produits

- Fours et accessoires de cuisson

- Lingotins

- Stratification de céramique

- Couper - Former - Texturer

- Maquillage et glaçure

- Polissage

- Cimentation et Mordançage

- Procédé Métal

- Procédé Zircone

- Procédé composite

- Mise en revêtement

- Enfournement - Dépouillage

- Adaptation

- Boîtes et emballage

- Pièces squelettiques

- Orthodontie

- Tous les produits

- Fabrication de modèles, mise en articulation

- Reproduction de modèle

- Cirage

- Instruments et équipements

- Pinces pour fils métalliques

- Fils métalliques

- Acryliques Ortho & additifs

- Acryliques pour plaques occlusales

- Thermoplastiques

- Meulage / coupage / sablage

- Polissage - Finition

- Boîtes et emballage

-

Produits

- Tous les produits

- Produits DenPlus

- Acryliques

- Tous les produits

- Résine DenPlus

- Résines à cuisson conventionnelle

- Résine pour cuisson par micro-ondes

- Résine fluide pour coulée

- Résines de réparation

- Résines auto-polymérisables pour porte-empreintes

- Résines pour regarnissage

- Résines orthodontiques

- Résines thermoflexibles

- Résines radiopaques

- Résines teintes de dent

- Abrasifs, Fraises, Polissoirs et Disques

- Tous les produits

- Abrasifs

- Fraises

- Tous les produits

- Mini-catalogue fraises au carbure Diaswiss

- Fraises au carbure pour pièce à main

- Fraises spécialisées

- Fraises au carbure pour moteur

- Fraises pour turbine haute vitesse

- Fraises Infiniti pour pièce à main

- Fraises avec revêtement nitrure de titane

- Fraises DLC (Diamond-Like-Carbon)

- Fraises diamantées électroplaquées

- Fraises diamantées frittées

- Fraises pour finition des bases molles

- Pour technique de fraisage parallèle

- Fraises pour zircone

- Fraises Typhoon

- Organisation fraises

- Disques

- Roues et pointes abrasives, polissoirs

- Tous les produits

- Roues abrasives et pointes pour acryliques

- Roues abrasives et pointes pour zircone

- Roues et pointes d’oxyde d’aluminium

- Roues et pointes en carbure de silicium

- Roues pour meulage sans chaleur (Heatless)

- Meules pour moteur

- Bandes abrasives

- Roues et pointes en polyuréthane

- Roues et pointes en caoutchouc

- Roues et pointes en silicone

- Mandrins

- Roues pour taille-modèle

- Accessoires

- Articulateurs et arcs faciaux

- Brûleurs

- Numérique

- Tous les produits

- Mini-catalogue Numérique

- Logiciels

- Scanners dentaires

- Impression 3D

- Usinage

- Céramiques

- Cires

- Dents

- Die et modèle

- Boîtes et Emballage

- Empreintes

- Tous les produits

- Accessoires pour matériaux d’empreinte

- Polysulfure

- Adhésifs pour porte-empreintes

- Alginates

- Base de caoutchouc

- Bols de mélange

- Enregistrement occlusal

- Pistolet et embouts mélangeurs

- Polyéther

- Porte-empreintes

- Masques gingivaux

- Mastic pour empreintes

- Nettoyants pour alginate

- Seringues pour alginate

- Thermoplastiques - Composés

- Vinyl Polyether Silicone (VPES)

- Vinyl Polysiloxane (VPS)

- Oxyde de zinc - Eugénol & Non-Eugénol

- Équipements

- Tous les produits

- Anti-éclabousseurs

- Bains ultrasoniques

- Balances

- Burins électriques/pneumatiques

- Chauffe-cire

- Clinique

- Collecteurs de poussières

- Détoureuse pour arche

- Échaudeuses pour cire

- Coulée métaux

- Foreuse à goujons

- Fournaises

- Hottes et purificateurs d’air

- Lampes

- Loupes

- Mélangeurs

- Mélangeurs pour hydrocolloïde

- Meuleuses/polisseuse à haute vitesse pour métal

- Micromoteurs - pièces à main

- Microscopes

- Moteurs

- Moulage sous vide

- Nettoyeurs à vapeur

- Nettoyeurs de prothèses

- Équipement à photopolymériser

- Polissoirs

- Pots à pression

- Presse Hydraulique

- Systèmes à injection

- Sableuse

- Spatules chauffantes

- Stérilisateurs et autoclaves

- Taille-modèles

- Trappes et bennes à plâtre

- Turbines haute vitesse

- Unité de soudage

- Unités de cuisson pour prothèse

- Vibreurs

- Instruments

- Matériaux photopolymérisants

- Meubles

- Moulage sous vide

- Orthodontie

- Pinceaux, Brosses et polissoirs

- Plâtres, pierres et revêtements

- Ponts & couronnes

- Prévention et cosmétique

- Produits chimiques

- Prothèses amovibles

- Tous les produits

- Résines pour base dentaire

- Regarnissage de prothèse

- Prothèses partielles

- Accessoires pour prothèses

- Tous les produits

- Caractérisation

- Crochets métalliques

- Crochets en plastique

- Feuilles séparatrices - mise en moufle

- Fibres

- Fils

- Presse à rebasage

- Jauges, Compas, Plan occlusal

- Liquide séparateur

- Matériaux à duplication

- Moufles et brides

- Moufles pour duplication

- Pâte isolante

- Plaques bases

- Polissage

- Treillis et renforts

- Sécurité

- Usage unique

-

Équipements

- Tous les produits

- Anti-éclabousseurs

- Bains ultrasoniques

- Balances

- Burins électriques/pneumatiques

- Chauffe-cire

- Clinique

- Collecteurs de poussières

- Détoureuse pour arche

- Échaudeuses pour cire

- Coulée métaux

- Foreuse à goujons

- Fournaises

- Hottes et purificateurs d’air

- Lampes

- Loupes

- Mélangeurs

- Mélangeurs pour hydrocolloïde

- Meuleuses/polisseuse à haute vitesse pour métal

- Micromoteurs - pièces à main

- Microscopes

- Moteurs

- Moulage sous vide

- Nettoyeurs à vapeur

- Nettoyeurs de prothèses

- Équipement à photopolymériser

- Polissoirs

- Pots à pression

- Presse Hydraulique

- Systèmes à injection

- Sableuse

- Spatules chauffantes

- Stérilisateurs et autoclaves

- Taille-modèles

- Trappes et bennes à plâtre

- Turbines haute vitesse

- Unité de soudage

- Unités de cuisson pour prothèse

- Vibreurs

-

Numérique

- Tous les produits

- Mini-catalogue Numérique

- Logiciels

- Scanners dentaires

- Impression 3D

- Tous les produits

- Imprimantes Shining 3D

- Imprimantes Phrozen

- Imprimante Renfert

- Imprimantes Flashforge

- Résines 3D

- Nettoyage

- Post-polymérisation

- Adhésifs, séparateurs, Rebasage, glaçure

- Usinage

- Dents

-

Fabricants

- Tous les produits

- 3M ESPE

- American Tooth Industries

- ASA Dental

- Astek Innovations

- Aurelia par Supermax Healthcare Canada

- Bausch

- Beaverstate Dental

- Besqual

- Brewer

- Buffalo Dental

- Canadian Hospital Specialities Ltd

- CMP Industries

- Crosstex

- Dedeco

- Defend

- DenPlus

- Dental Creations

- Dentalfarm

- Dentsply

- Detax

- Diaswiss

- Dreve

- DTS

- Esma Incorporated

- exocad

- FAG Dentaire

- Flashforge

- Foredom Electric

- Garreco

- GC America

- Grobet

- Hager

- Hammacher

- Handler

- Hatho

- Invent Dental

- Isonic

- Kerr

- Keystone Industries

- Kube Innovation

- Lang Dental

- Lascod

- LeoneAmerica

- Maestro 3D

- Malzer Dental

- Meta Dental

- Micrylium

- MPF Brush Co

- Myerson

- Nabertherm

- NK-Optik

- Pac-Dent

- Phare Médica

- Phrozen

- Pi Dental

- Prodont Holliger

- pro3dure medical

- PRO-TECH

- Protechno

- Quatro Air

- Ransom & Randolph

- Ray Foster

- Razertip

- Reliable Corporation

- Renfert

- Saeyang

- Scantist 3D

- Schottlander

- Shenpaz

- Shining 3D

- Song Young

- Synca

- Tapmaster

- Tokuyama Dental

- Uvitron International

- Vacalon

- Vita

- Wells Dental

- Whip Mix

- Winder Research

- Yamahachi Dental

- Yates Motloid

- Yeti

Voici la résine à modèle dentaire DenPlus pour imprimantes 3D. Développée selon des exigences strictes, cette résine offre résistance, précision et prévisibilité à un prix abordable. Elle peut être imprimée à une épaisseur de couche de 50 µm ou 100 µm et est convenable pour tous les types de modèles dentaires. Elle est compatible avec une varité d’imprimantes DLP et LCD.

- Scannable

- Précise

- Dure

- Testés sur imprimantes DLP et LCD

- Couleurs : Beige, Gris, Blanc

- Quantité: 1 kg

La validation d’imprimante pour notre résine 3D est réalisée à l’interne pour assurer un contrôle total et la cohérence des résultats. Notre méthodologie implique des tests d’impression exhaustifs et un réglage minutieux des paramètres du matériau jusqu’à ce que les restaurations de référence, qui comprennent des couronnes et des ponts en zircone ainsi que des pièces squelettiques coulées, s’adaptent aux modèles imprimés de la même manière qu’ils s’adaptent aux modèles en pierre originaux dont ils sont issus.

Consulter la section Documentation et Vidéos ici-bas pour obtenir les paramètres des imprimantes validées.

| Couleur | Beige, Gris, Blanc |

| Visicosité | 220~280 cps @25 °C |

| Résistance à la traction | 49-56 MPa |

| Module de traction | 1640-1740 MPa |

| Résistance à la flexion | 78-83 MPa |

| Module de flexion | 2080-2160 MPa |

| Allongement à la rupture | 10-13% |

| Dureté | 85 D |

Imprimantes validées

La liste d’imprimantes ci-dessous ne couvre que celles validée directement par DenPlus Inc. Pour obtenir les paramètres d'une de ces imprimantes, veuillez envoyer la demande à info@denplus.com.

Imprimantes |

|

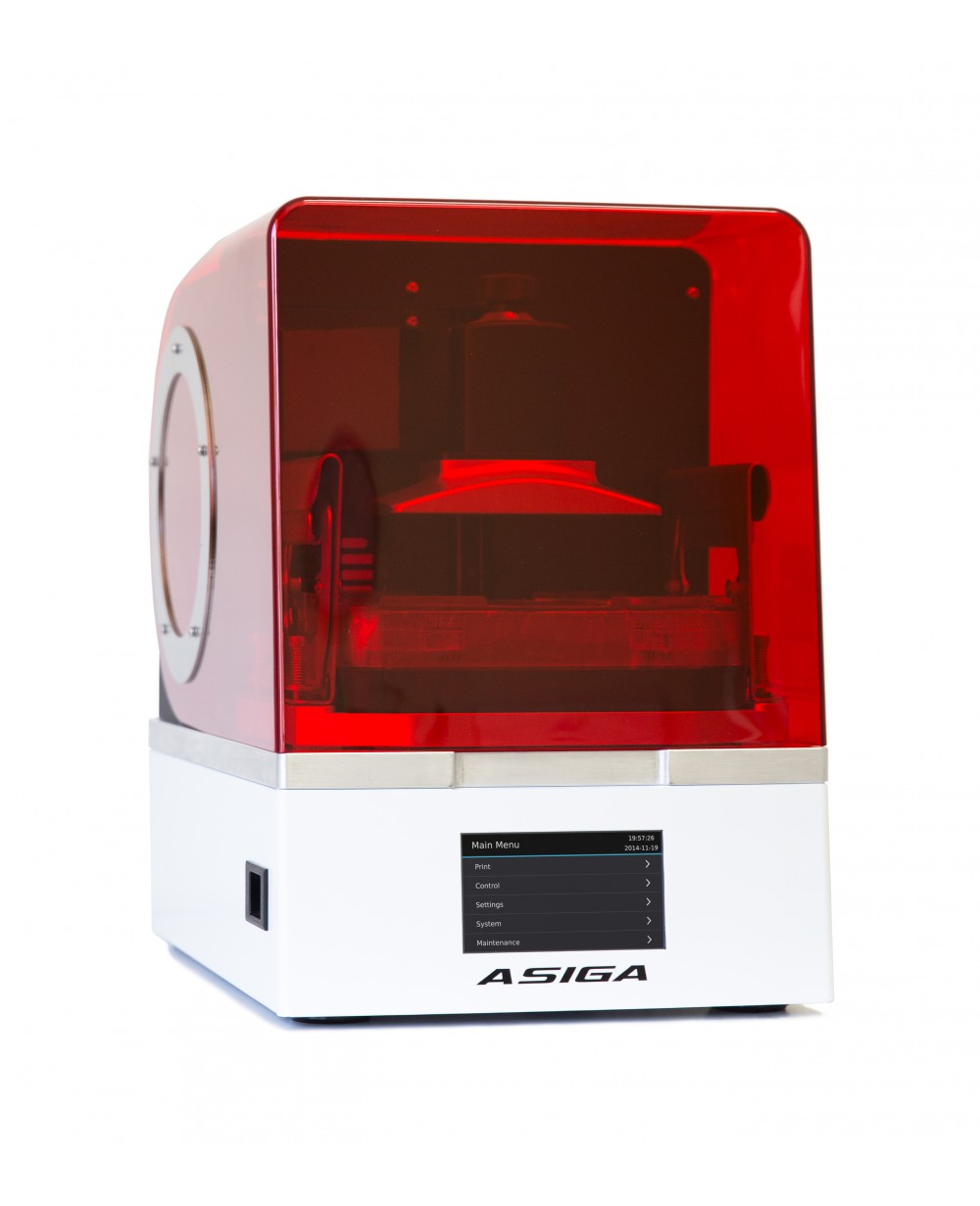

Asiga Max UV385, Pro4K UV385

|

|

Shining 3D AccuFab-D1s

|

|

Shining 3D AccuFab-L4D/L4K

|

|

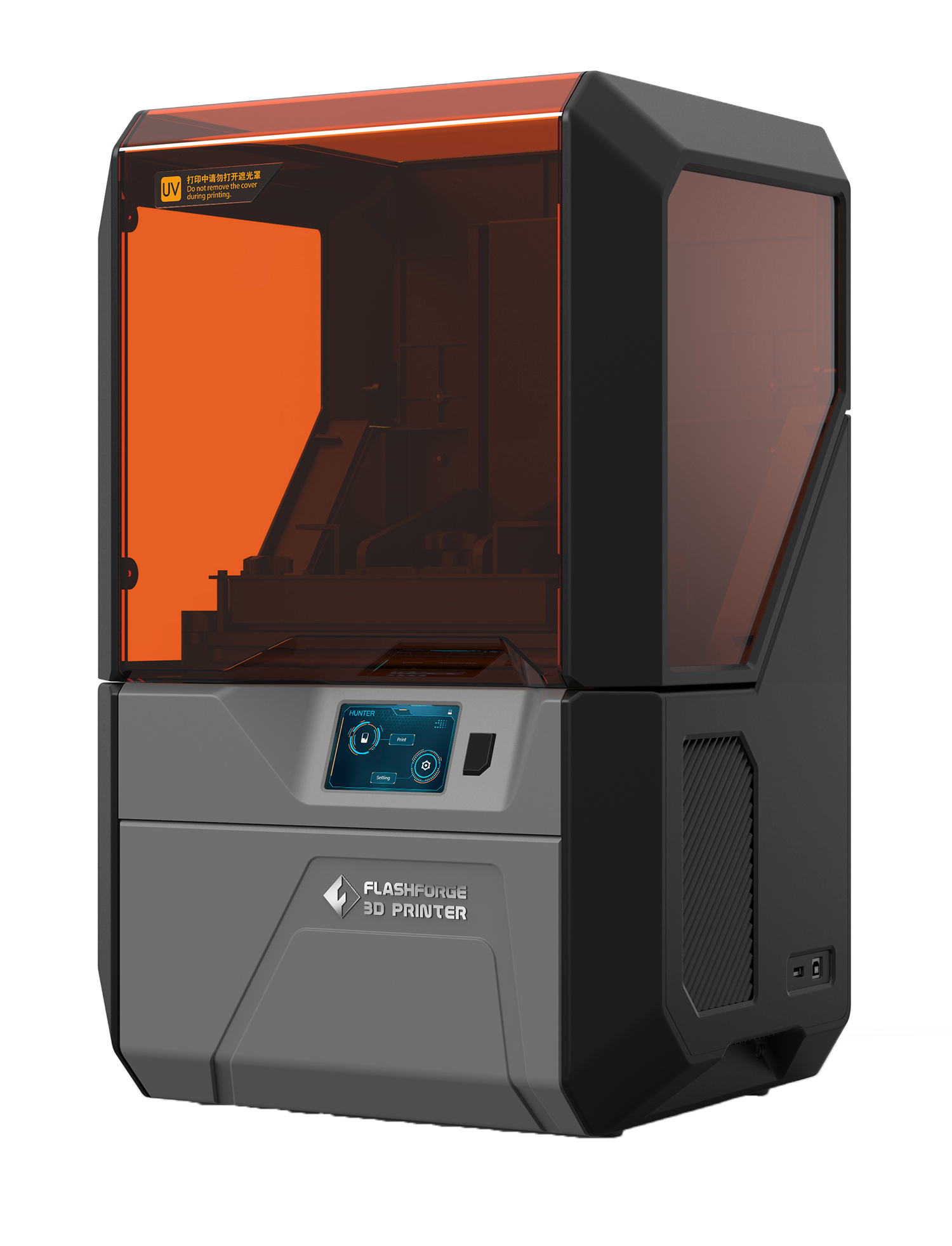

Flashforge Hunter (sur FlashDLPrint 2.3.0 ou FlashDental 1.2.3 ou plus)

|

|

Shining 3D AccuFab-D1

|

|

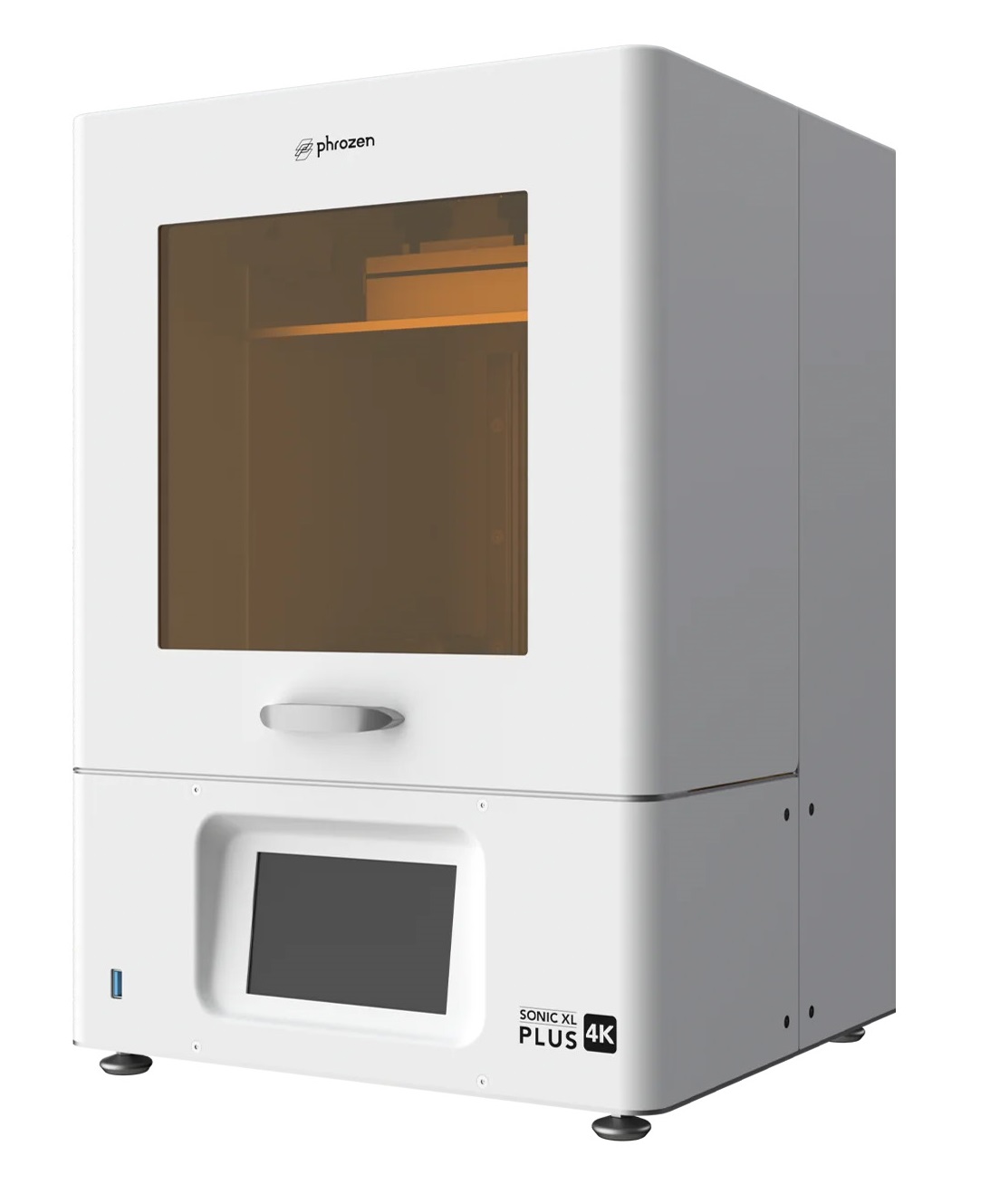

Phrozen Sonic XL 4K 2020 (sur Phrozen 3D ou Phrozen DS)

|

|

Phrozen Sonic 4K, Sonic 4K 2022 (sur Phrozen 3D ou Phrozen DS)

|

|

Phrozen Sonic XL 4K 2022, XL 4K PLUS (sur Phrozen DS)

|

POST-DURCISSEMENT

- Source LED 405nm (sans apport de chaleur):

- 30 mW/cm2 (ex: FabCure 1) - 40 minutes par coté (80 min. total)

- 70 mW/cm2 et plus (ex: FabCure 2) - 34.5 minutes total - OTOFLASH G171: 2000-2400 flashs par côté.

Laisser les modèles refroidir jusqu' à température ambiante avant de les utiliser.

REMARQUE: À noter que la résine blanche jaunit un peu après le post-durcissement mais redevient blanche après 24-48 heures.

Avez-vous besoin?

Produits complémentairesInfolettre

Pour recevoir nos nouvelles et promotions

© 2025 DenPlus Inc. | Copyright | Conception Web : ViGlob